Click for technic details

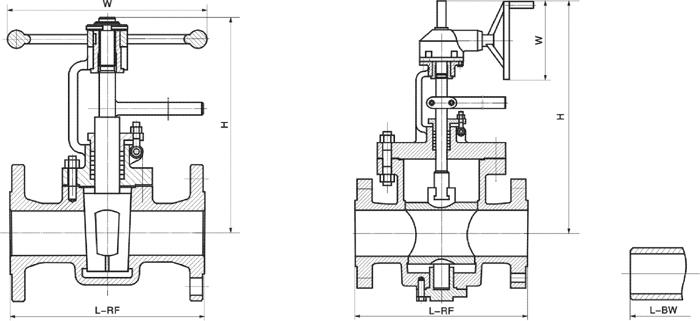

Flanged end lifting pulg valve acc. to ANSI is applicable to the cutting and connection for pipeline medium that are used in various industries such as petroleum, chemical industry, pharmacy, chemical fertilizer, power industry etc under normal pressure of Class 150 to 1500 lbs and working temperature of -29¡æ~550¡æ.

Structural formation: BC

Operating: Wrench, worm & worm gear, pneumatic, electric actuated

Design: API 599; API 6D

Face to face: ASME B16.10

Flange end: ASME B16.5

Test & inspection: API 598; API 6D

|

Nominal Pressure (lbs) |

Shell Test (MPa) |

Sealing Test (MPa) |

Suitable Temp. (¡æ) |

Suitable Medium |

|

150 |

3.0 |

2.2 |

¡Ü180¡æ |

Water, oil & gas |

|

300 |

7.5 |

5.5 |

|

600 |

15.0 |

11.0 |

|

900 |

22.5 |

16.5 |

|

1500 |

37.5 |

27.5 |

|

Body & Bonnet |

Cast Steel ASTM A216 WCB, Stainless Steel ASTM A351 CF8, CF8M, CF3, CF3M |

|

Plug |

ASTM A182 F6a, ASTM A182 F22, ASTM A182-F304, F316, F321, F304L, F316L |

|

Gasket |

Flexible graphite+SS304, PTFE |

|

Wrench |

ASTM A216 WCB |

|

DN |

L mm |

H mm |

W mm |

Weight kg |

|

150 lbs |

|

15 |

108 |

190 |

280 |

9 |

|

20 |

117 |

195 |

280 |

10 |

|

25 |

127 |

225 |

280 |

11 |

|

32 |

140 |

260 |

300 |

17 |

|

40 |

165 |

280 |

300 |

19 |

|

50 |

178 |

310 |

300 |

23 |

|

65 |

190 |

340 |

300 |

25 |

|

80 |

203 |

395 |

300 |

32 |

|

100 |

229 |

435 |

300 |

55 |

|

125 |

254 |

470 |

340 |

82 |

|

150 |

267 |

535 |

400 |

98 |

|

200 |

292 |

590 |

450 |

130 |

|

250 |

330 |

630 |

450 |

178 |

|

300 |

356 |

680 |

500 |

250 |

|

350 |

381 |

720 |

500 |

380 |