Click for technic details

It is special for controlling the noncorrosive or the strong corrosive media. Its body inner surface is unlined or lined with different fluorine plastics which can be selected to suit with different working temperatures and fluid pipelines.

Suitable temperature: ¡Ü85¡æ, ¡Ü100¡æ, ¡Ü120¡æ, ¡Ü150¡æ according to the materials of lining and diaphragm

There being no weir in through way type diaphragm valves, fluid passes straightly through inside valve cavity, so that they are especially applicable for viscous fluid, cement grout and perceptible fluid. Compared with weir type diaphragm, the diaphragm stroke of through way type is comparatively longer. That is to say, this structure can limit the selection range of synthetic rubber.

Design & manufacture: GB12239

Face to face: JB1688, GB12221

Flange ends: JB78, GB4216

Test for lining layer: Electro spark detecting

Test: GB/T13927

|

Body & Bonnet |

Cast Iron, Carbon Steel, Stainless Steel |

|

Lining |

Unlined, Fluorine Plastic |

|

Diaphragm |

Fluorine Plastic |

|

Disc |

Cast Iron, Stainless Steel |

|

Stem |

Carbon Steel, Stainless Steel |

|

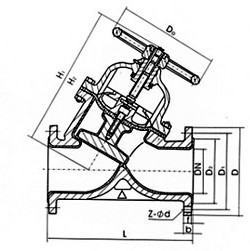

DN |

L |

D |

D1 |

D0 |

n-¦Õd |

H |

H1 |

Weight kg |

|

PN10 |

|

25 |

145 |

115 |

85 |

120 |

4-14 |

178 |

190 |

|

|

32 |

160 |

140 |

100 |

140 |

4-18 |

196 |

217 |

|

|

40 |

180 |

150 |

110 |

140 |

4-18 |

196 |

217 |

14 |

|

50 |

210 |

165 |

125 |

200 |

4-18 |

219 |

240 |

20 |

|

65 |

250 |

185 |

145 |

200 |

4-18 |

264 |

272 |

29 |

|

80 |

300 |

200 |

160 |

280 |

4-18 |

285 |

315 |

42 |

|

100 |

350 |

220 |

180 |

320 |

8-18 |

352 |

383 |

61 |

|

125 |

400 |

250 |

210 |

320 |

8-18 |

470 |

515 |

79£®5 |

|

150 |

460 |

285 |

240 |

400 |

8-22 |

508 |

554 |

150 |

|

200 |

570 |

340 |

295 |

500 |

8-22 |

602 |

660 |

236£®5 |

|

250 |

680 |

395 |

350 |

500 |

12-22 |

708 |

786 |

|

|

300 |

790 |

445 |

400 |

|

12-22 |

|

|

|