Click for technic details

The wafer butterfly valves are widely applied, thanks to their multiple functions of regulation and on-off valves; they are a good solution whenever needed compact dimensions and reduced weight. Thanks to the EPDM gasket and to the epoxy coating, the wafer butterfly valves can be installed in drinking water plants, but they can also be applied for sewage or brackish water with stainless steel disc and body not in touch with the fluid. The wafer butterfly valves are manufactured as centric type disc, they can stand both directions of fluid and are maintenance-free. With EPDM gasket, they can stand maximum 130¡ãC temperature. The wafer butterfly valves can be installed between welding neck flanges EN PN 10-16 and ANSI #150, without any need of additional flange gaskets. Such valves can be installed in any position. The wafer butterfly valves come with lever (standard execution); reducing gear, pneumatic operator with single or double effect, electric actuator on request.

Design & manufacture: BS 5155, MSS SP-67

Face to face: BS EN558-2 series 20, API 609

Flange type: ANSI B16.10 Class 125

Other flange types are available

|

Body |

Ductile Iron |

|

Disc |

Ductile Iron |

|

Shaft |

Stainless Steel |

|

Sealing face |

EPDM |

|

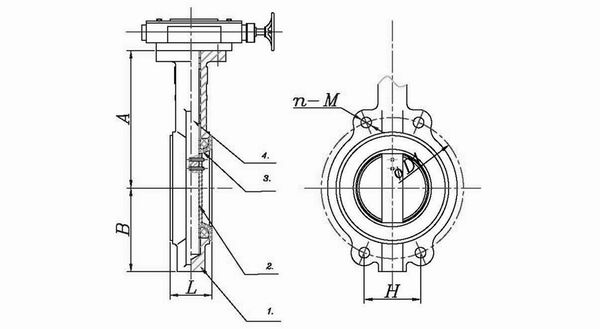

Size |

L mm |

H mm |

A mm |

B mm |

Weight kg |

|

150 lbs |

|

150 |

55.8 |

92.4 |

226 |

133 |

16.3 |

|

200 |

60.6 |

114.2 |

260 |

175 |

27.7 |

|

250 |

65.6 |

93.7 |

292 |

203 |

33.5 |

|

300 |

76.9 |

111.8 |

337 |

242 |

49 |

|

350 |

76.9 |

123.2 |

368 |

267 |

59 |

|

400 |

86.5 |

105.3 |

400 |

301 |

88 |

|

450 |

105.6 |

113 |

422 |

327 |

123 |