Click for technic details

Check valves are generally used to protect pumps or similar equipment, allowing the flow only in one direction and preventing flow reversal due to back pressure. The pressure seal swing check valves are designed to close quickly and quietly and to produce a low pressure drop in the pipeline.

Design & manufacture: ANSI B16.34

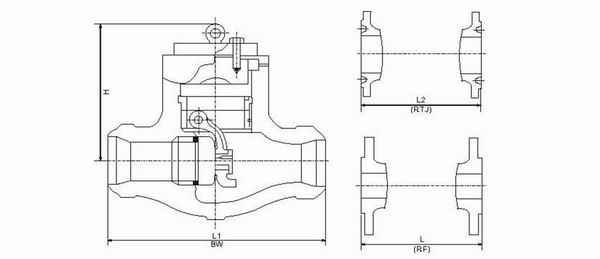

Face to face: ANSI B16.10

Flanged ends: ANSI B16.5

Welded ends: ANSI B16.25

Inspection & test: API 598

|

Nominal Pressure (lbs) |

Test Pressure(psig) |

|

Shell (hydro.) |

Seat (hydro.) |

Seat(air) |

|

900 |

3350 |

2442 |

80 |

|

1500 |

5626 |

4078 |

80 |

|

2500 |

9275 |

6787 |

80 |

|

Body & Bonnet |

Cast Steel ASTM A216 WCB, Stainless Steel ASTM A351 CF8, CF8M, CF3, CF3M |

|

Disc |

Cast Steel ASTM A216 WCB, Stainless Steel ASTM A351 CF8, CF8M, CF3, CF3M |

|

Gasket |

Flexible graphite+SS304, PTFE |

|

Sealing face |

ASTM A182 F6a, ASTM A182 F22, ASTM A182-F304, F316, F321, F304L, F316L |

|

DN |

L mm |

H mm |

Weight kg |

|

900 lbs |

|

2¡± |

368 |

188 |

50 |

|

2 1/2¡± |

419 |

210 |

65 |

|

3¡± |

384 |

210 |

80 |

|

4¡± |

457 |

216 |

124 |

|

6¡± |

610 |

368 |

256 |

|

8¡± |

737 |

511 |

513 |

|

10¡± |

838 |

614 |

940 |

|

12¡± |

965 |

705 |

1450 |

|

14¡± |

1029 |

736 |

1725 |

|

16¡± |

1130 |

756 |

1834 |

|

|